Uprights Lead

Carnegie Mellon Racing (2023-24)

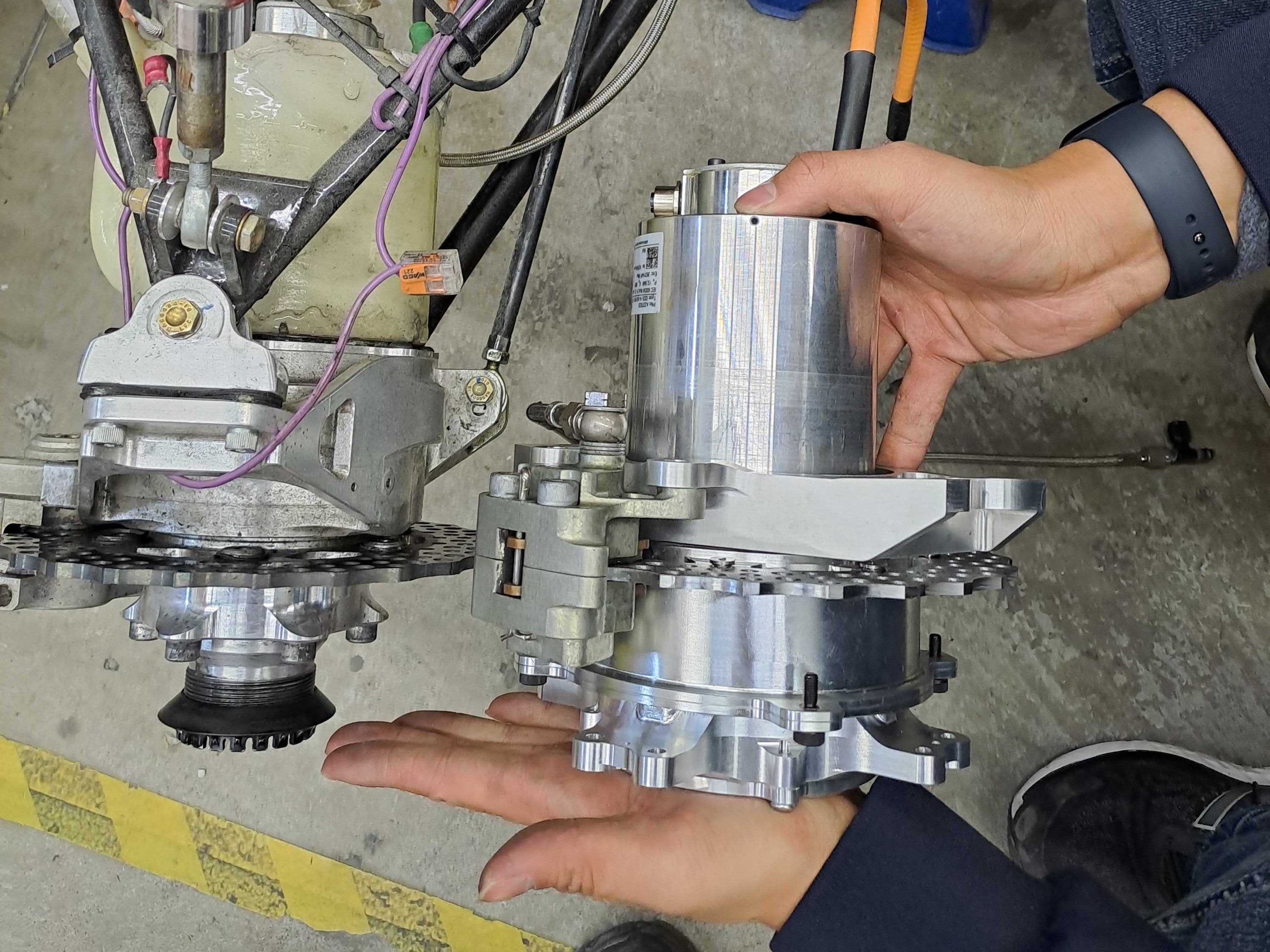

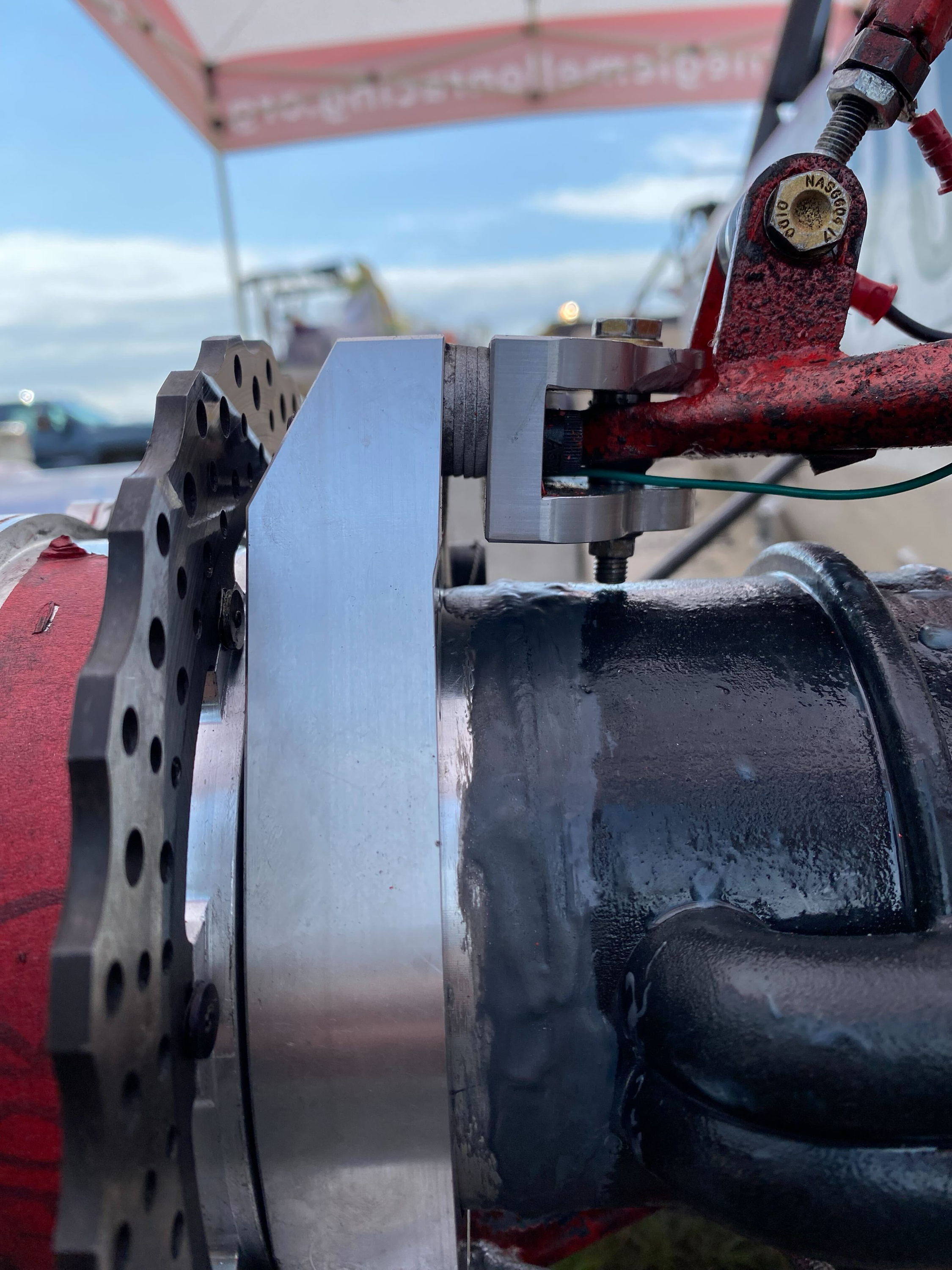

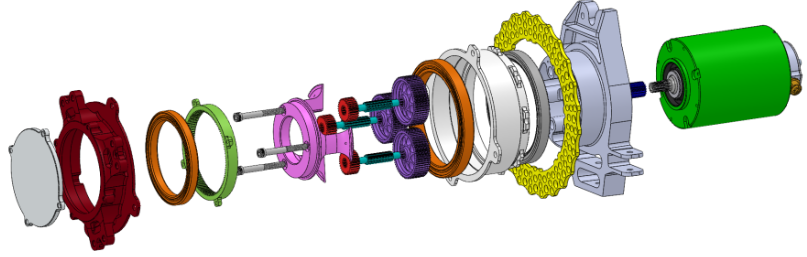

I led the complete redesign of the uprights to integrate lightweight carbon fiber wheels into our 4-wheel-drive hub motor powertrain. The uprights are the critical structural element of the powertrain asssembly; they support the brake calipers, motors, and bearings (which, in turn, support the wheel hubs), house our planetary gearset, and ultimately link the powertrain assembly to the suspension and chassis.

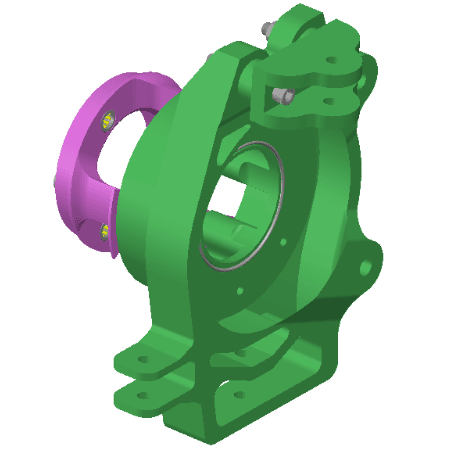

Our redesign shifted from an internal mounting configuration to one in which the hubs mount externally around the upright. This change necessitated a two-part design, replacing the previous single-piece configuration.

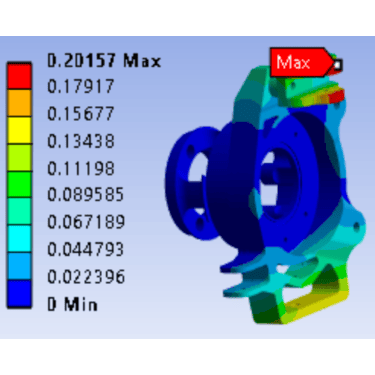

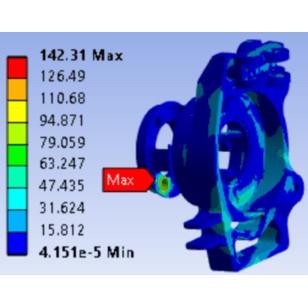

Through detailed hand calculations and finite element analysis, I achieved a 5% mass reduction in the uprights while enhancing the design for manufacturability. Overall, the powertrain's mass was reduced by 15% (approximately 5.6 kg) across all four wheels—a significant improvement considering that unsprung mass (mass not supported by the suspension) greatly impacts vehicle performance. The images below show FEA results for one of the load cases.

The parts were 5-axis CNC machined by a sponsor. I produced detailed drawings and worked closely with the sponsor to ensure that the parts were toleranced appropriately.

Beyond the structural improvements, the project involved close collaboration with the suspension and vehicle dynamics teams to optimize attachment points and maintain the desired vehicle dynamics. This effort also helped improve interteam communication compared to previous years.