Deployable Sunshade for NASA's Proposed LUVOIR

Project Overview

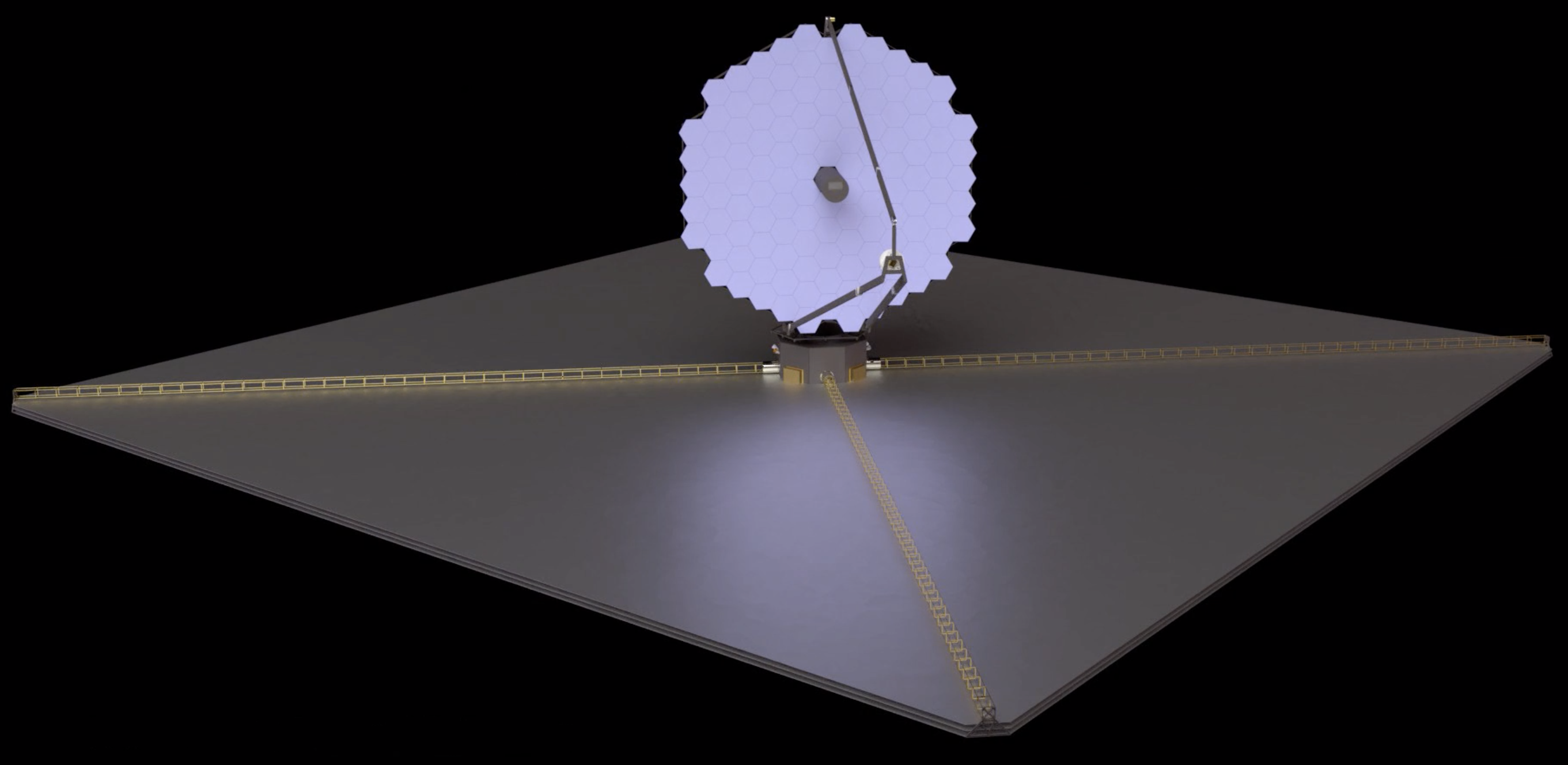

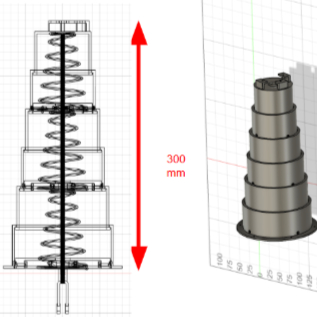

Our team set out to design and prototype a three-layer deployable sunshade for NASA’s proposed LUVOIR telescope ( Large Ultraviolet Optical Infrared Surveyor). Once deployed, it blocks stray and unintended light while shielding the telescope’s instruments from thermal loads, ensuring a clear and stable environment for high-precision observations. Each membrane layer is designed to stretch 20 m by 20 m and be spaced 10 cm apart in orbit, yet fit within a 0.5 m × 0.5 m × 0.3 m stowed volume. That tight constraint—essentially minimizing launch volume—drove our entire approach. After exploring various concepts and iterating on folding methods, we arrived at a working scaled prototype that demonstrates the core functionality of our system, from the central hub to the coordinated membrane deployment.

Membrane Folding & Integration

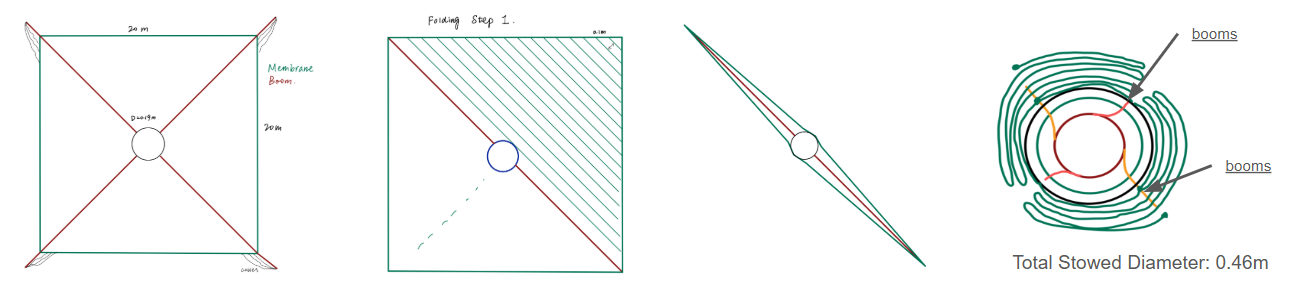

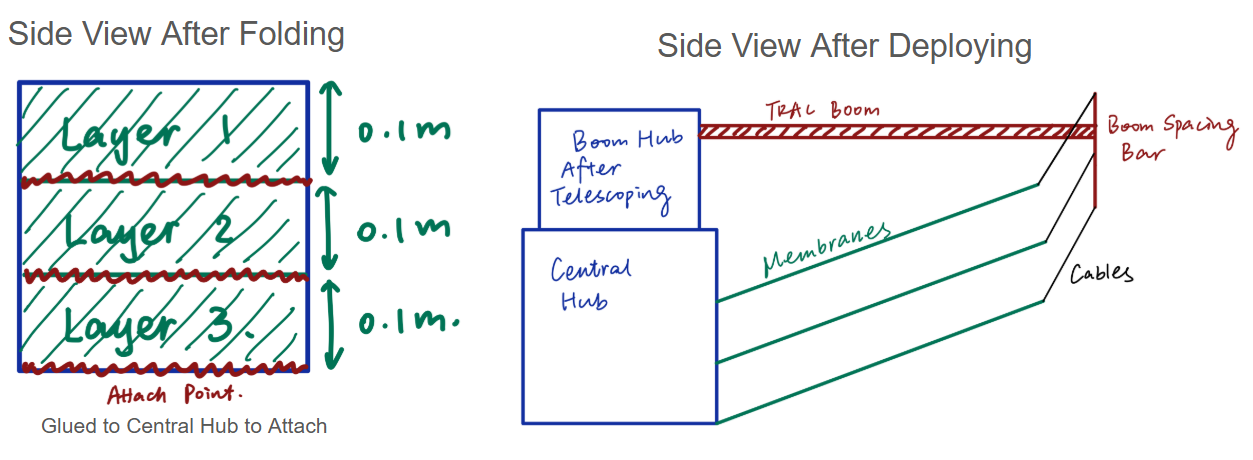

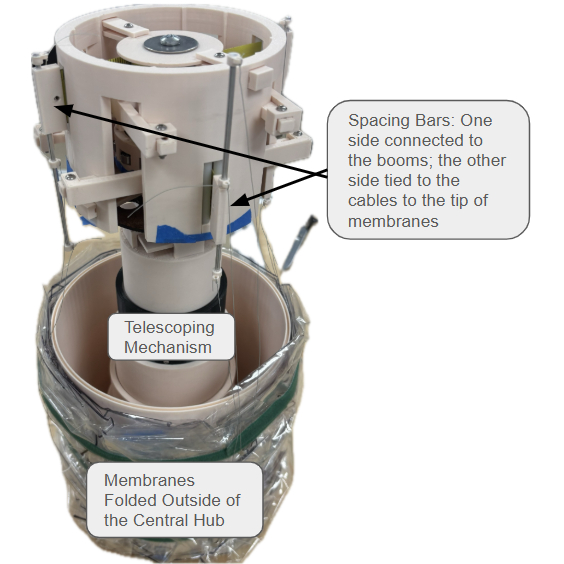

A key focus was developing a compact folding scheme so that all three membrane layers can stow around a central hub rather than being stacked on top of a larger, boxy framework. By folding each membrane along two main axes—first in a “Z” pattern, then wrapping the resulting strip around the hub—we achieved a highly space-efficient layout. This central-hub approach leverages circular cross-sections to cut down on wasted space. Traditional designs might pack each membrane layer on a flat 0.5 m × 0.5 m panel, but our careful geometry calculations showed that rolling and folding around a smaller cylindrical volume yields a more minimal stowed footprint.

Novel Boom Deployment Mechanism

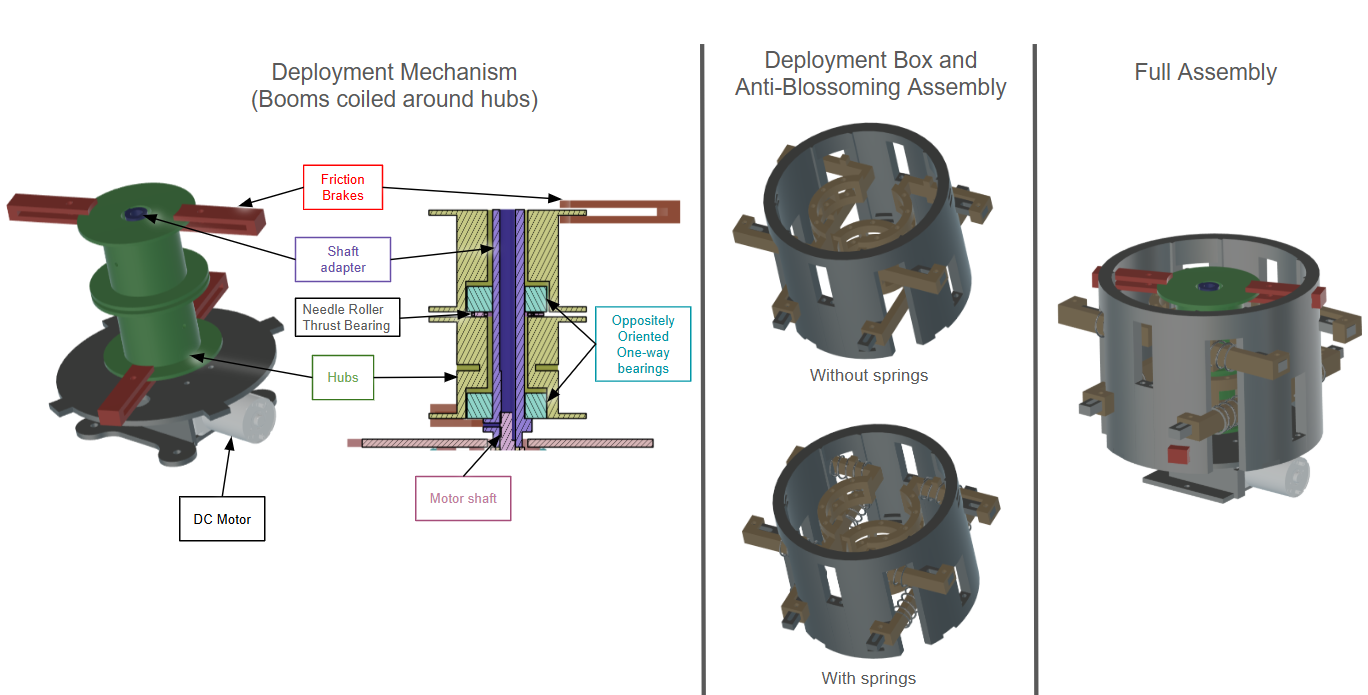

Our deployment occurs in two steps. First, a spring-loaded telescoping mechanism elevates the booms and spacer bars above the membranes, preparing them for deployment. Next, our novel boom deployment mechanism takes over.

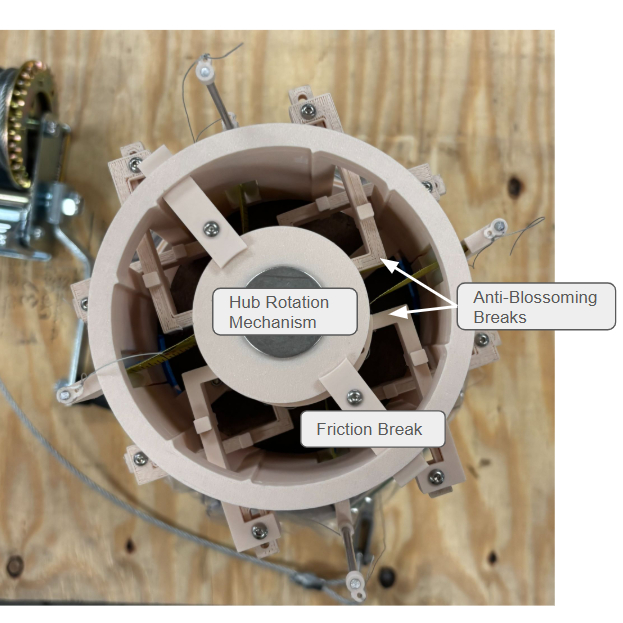

Because our membranes are folded around the hub in multiple layers, sequential deployment is essential—one set of corners must fully uncoil before the other. Instead of using two motors (which would exceed our stowed volume limits), I designed a sequential deployment system using coaxial booms. This design features two nested cylindrical hubs, each with a one-way bearing. A single motor drives both hubs in opposite directions, uncoiling one set of booms first and then reversing to deploy the second set. The telescoping mast raises the assembly clear of the hub to prevent interference.

In a flight design, each boom would be constructed from TRAC-style tapes that uncoil radially and remain stiff when extended. A small spacing bar at the tip of each boom attaches to the membrane corners, ensuring a precise 10 cm gap between layers. For our prototype, we used simple tape measure cross-sections.

Prototype Deployment Video

Here is the video of our prototype deployment!