Aerodynamics & Composites Team Captain

Carnegie Mellon Racing (2022-23)

I served as the Aerodynamics and Composites team captain for Carnegie Mellon Racing’s 2022–2023 electric race car. CMR is a student organization that designs and builds an electric racecar from scratch every year, which we then compete with at FSAE events in the summer. This car finished second out of 69 teams at Formula SAE Michigan, first place amongst US teams. My six-person sub-team was responsible for the design, analysis, manufacturing, and testing of all aerodynamic components. This is probably my the project I'm most proud of as it really took a full year of intense effort under tight timelines, and had a pretty great payoff at the end :)

Design & Analysis

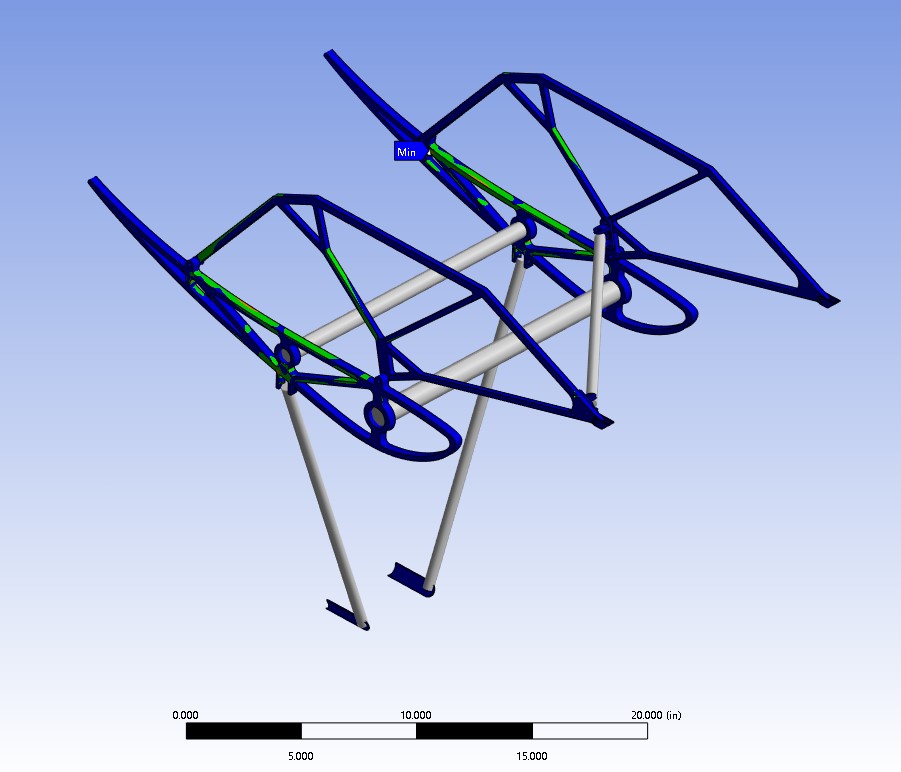

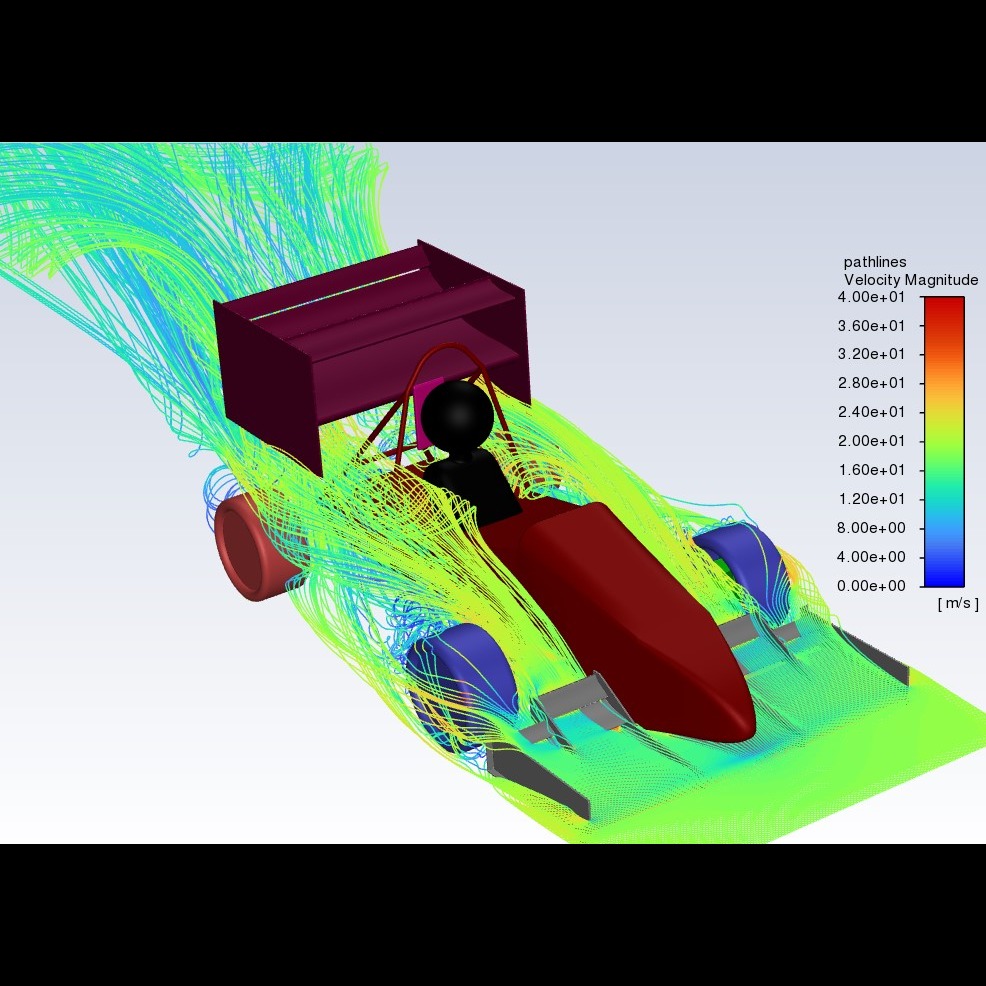

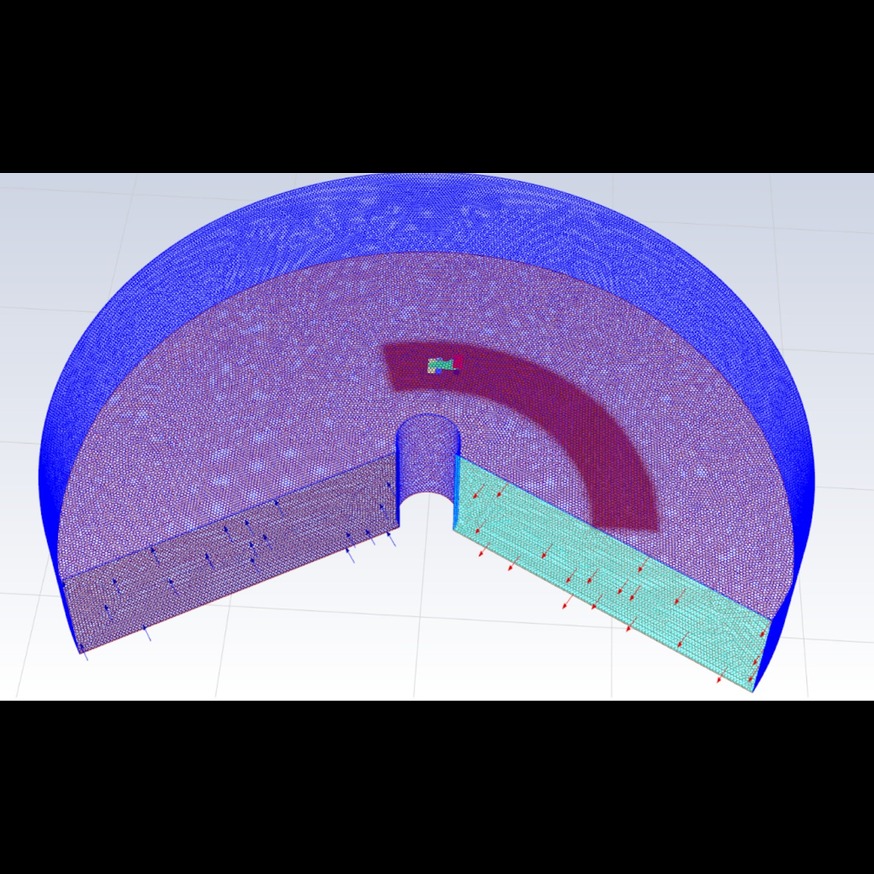

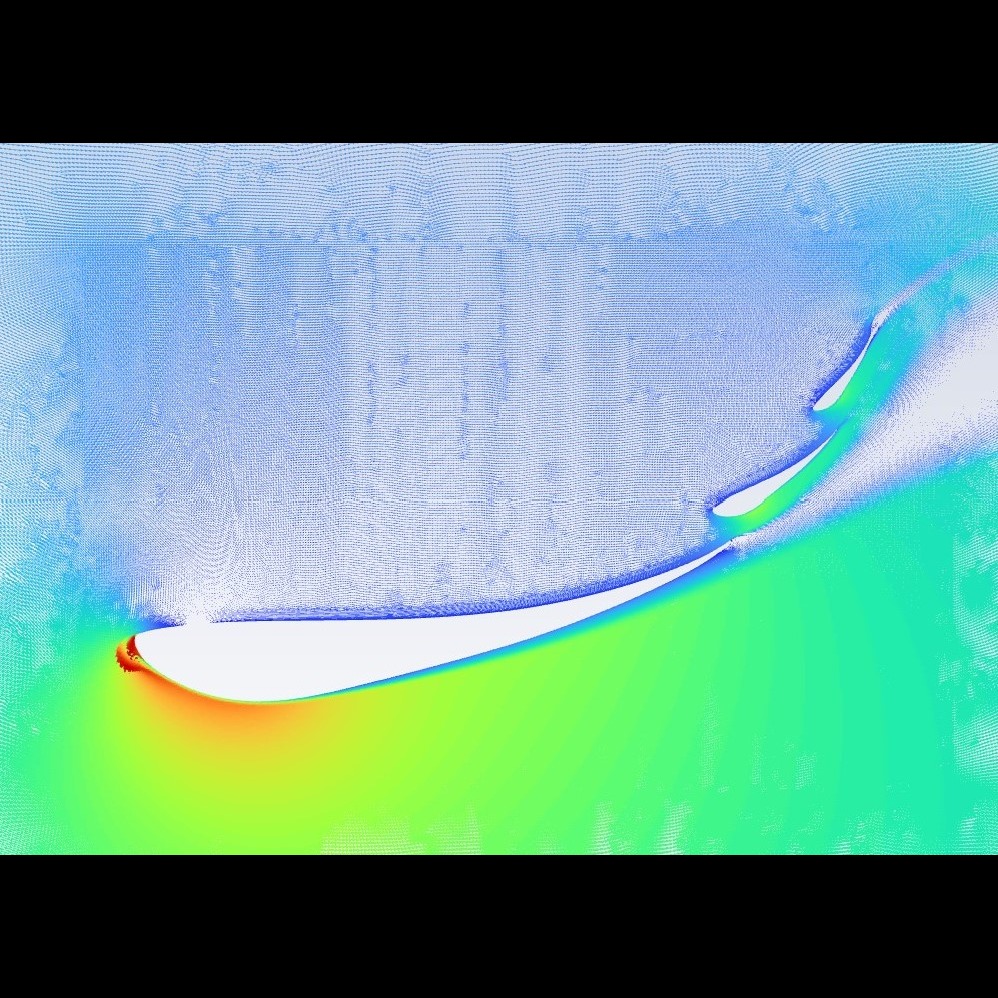

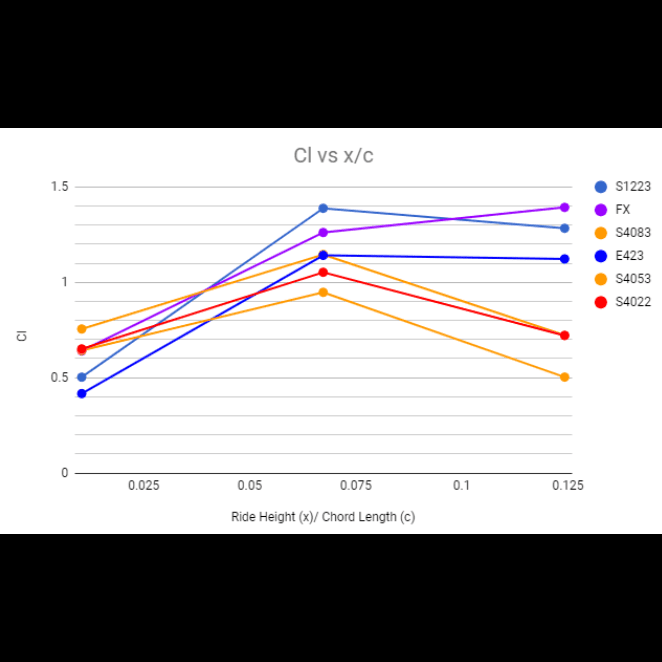

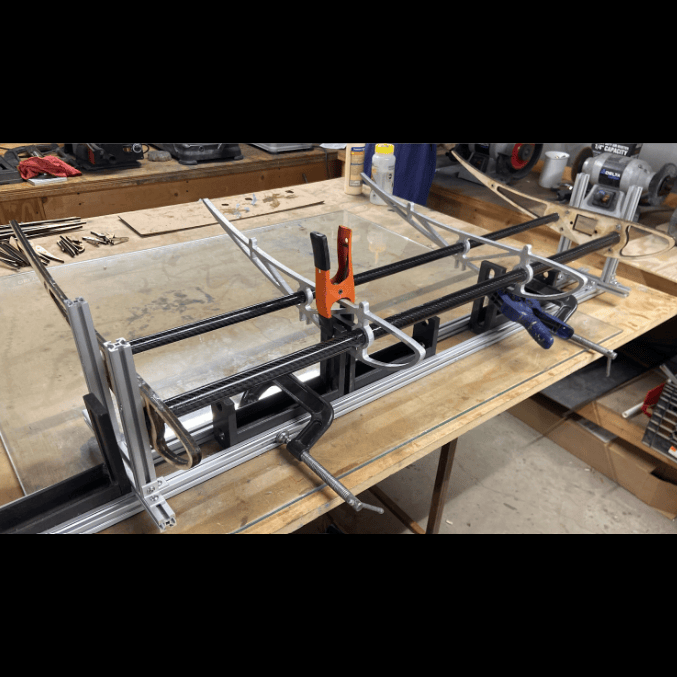

This project involved both structural and aerodynamic design. We used Ansys Fluent to run computational fluid dynamics (CFD) simulations, achieving a 10% increase in downforce while reducing the mass of our aerodynamic package by 30%. We also incorporated active aerodynamics (DRS) for the first time in team history, allowing for adjustable angles of attack on our rear wing to optimize drag and downforce on the track. For structural design, we utilized a rib-spar structure in both the front and rear wing, optimizing for the lightest possible design. Analysis was done with hand calcs and then in Ansys FEA, including the use of topology optimization to make the lightest possible rib shape with AI.

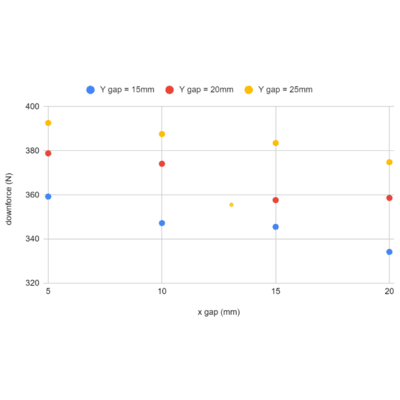

At every stage in the design process, we utilized our team's lap simulation software to evaluate tradeoffs in key variables, mainly trading off changes in downforce, drag, and mass. By utilizing aerodynamic principles/intuition and running geometric studies, we did our best to optimize a huge state space of variables to achieve the lowest possible lap time.

Manufacturing & Testing

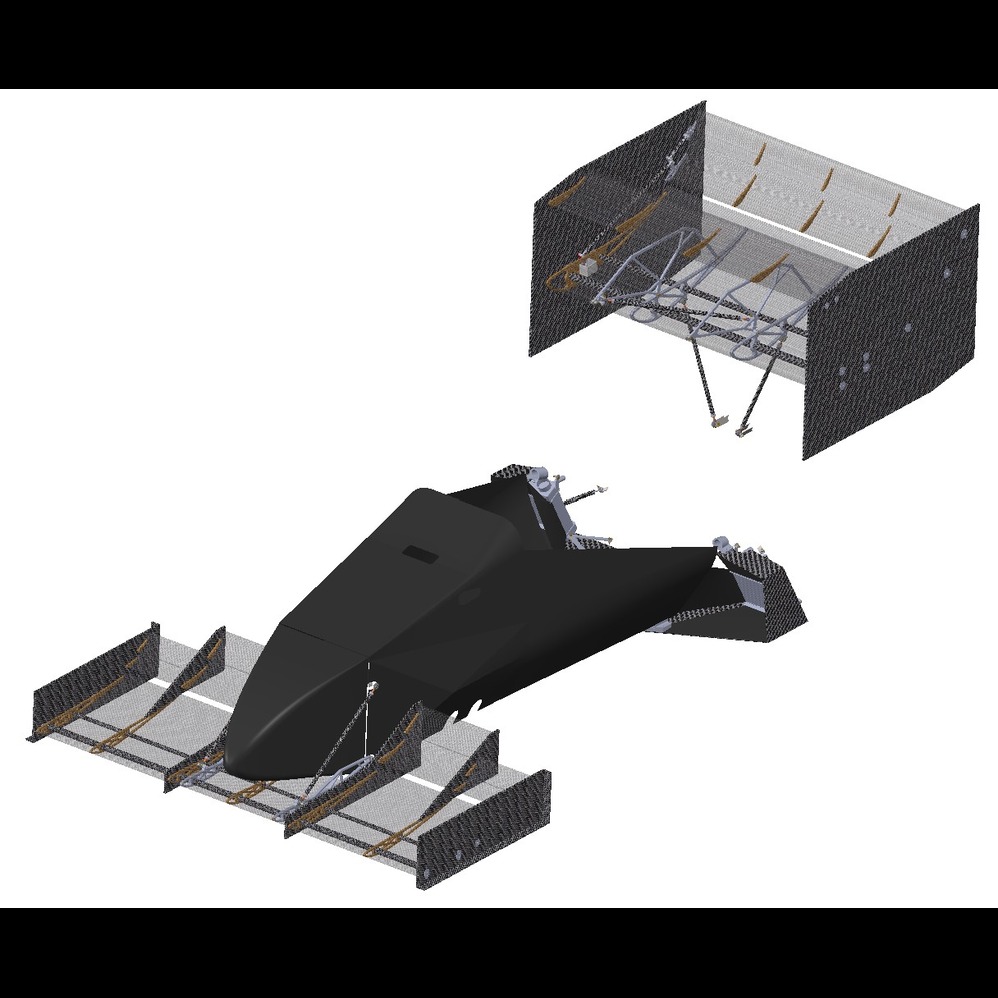

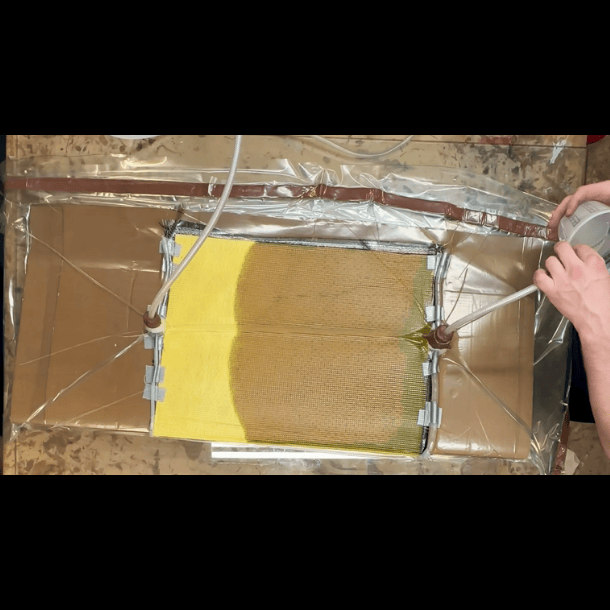

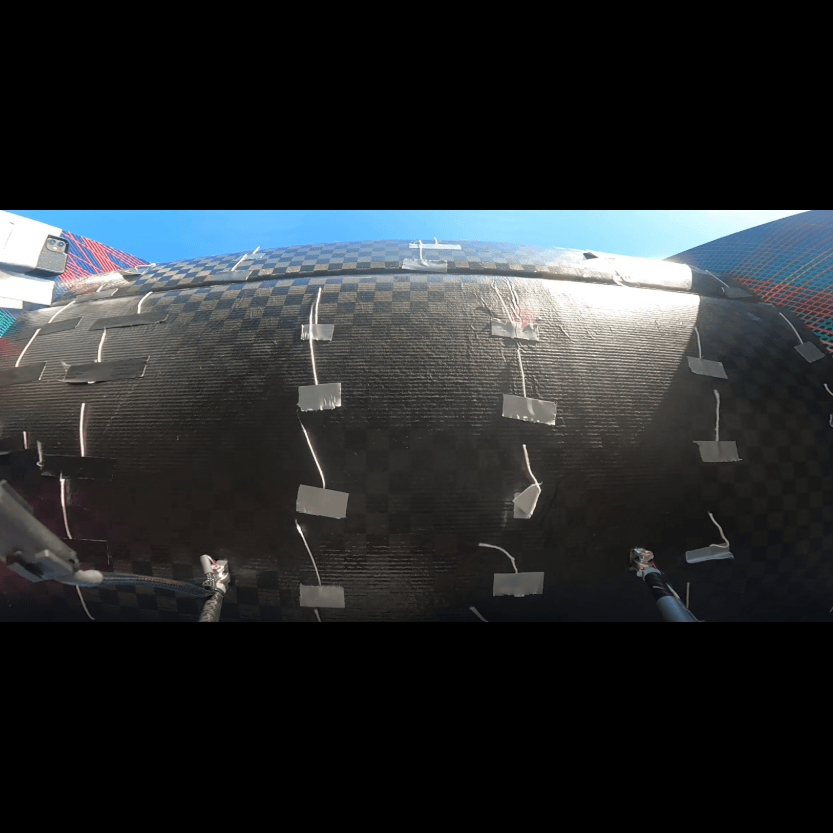

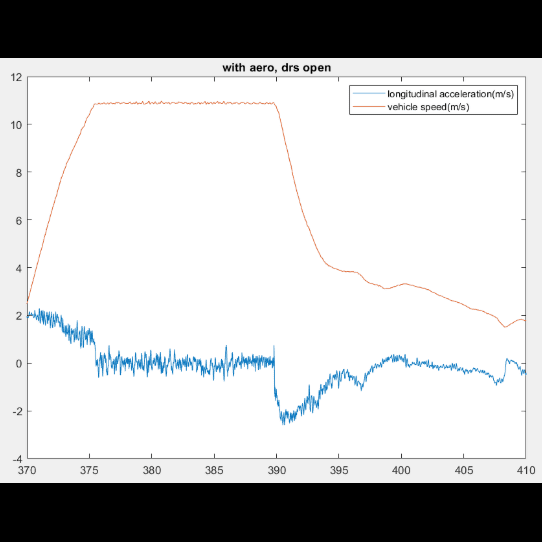

In manufacturing, we performed more than 20 carbon fiber layups, both wet and through resin infusion (pictured), and machined parts (using a CNC, waterjet, mill, laser cutter, 3D printer, etc.) under tight production schedules. This year's car was actually the earliest finished car in CMR's history (done in March) giving us a full 2 months for tuning and driver practice. Our comprehensive testing plan included downforce measurement via load cells in our suspension, coast down tests to estimate our drag coefficient (graph pictured), flow visualization using strings (pictured), and real-world performance data collection, which validated our CFD predictions and helped quantify the aerodynamic gains of our package.

Results

The car placed first in the US, which made me happy enough to perform a load test of the rear wing with the weight of myself and the trophy (it passed).